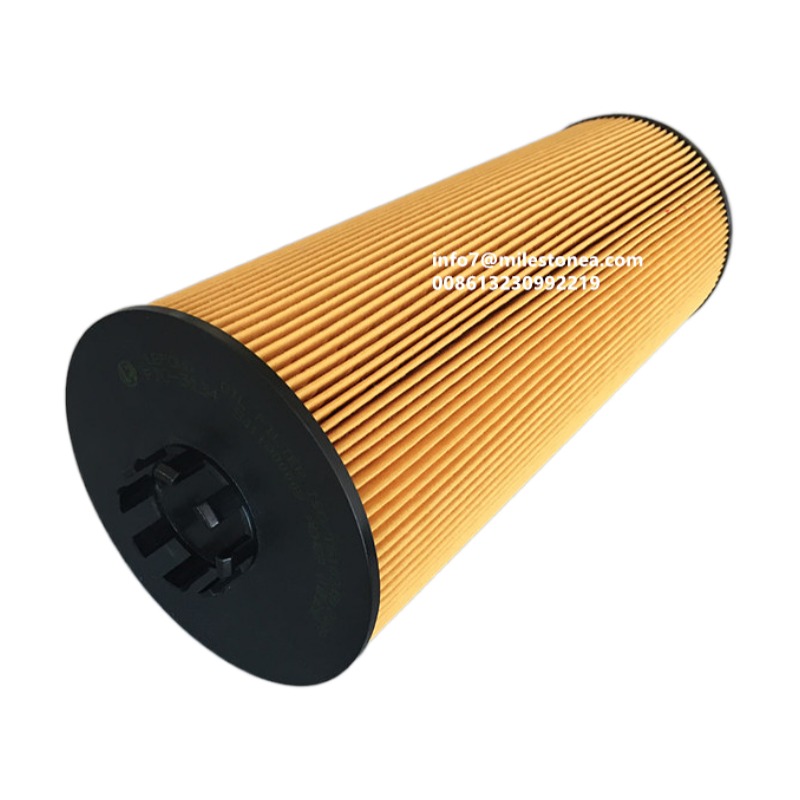

Izihluzi zeFactory Spin-on-on 1012N-010 LF3349 yeSahlulo seNjini

Factory Oil Spin-on Izihluzi I-1012N-010 LF3349 yeCandelo leNjini

Iimodeli ezisebenzayo: Cummins

Injini esebenzayo: K50

Imodeli yesixhobo esisebenzayo: P126T1

Akukho valve yokukhangela Akukho valve yokudlula

Ingqiqo eqhelekileyo yezihluzi ezilungileyo nezimbi

Zonke izihluzi zikhusela iindawo ze-injini, zicoca kwaye zandise ubomi benkonzo ye-injini.Ukusuka kumphezulu weefilitha ezahlukeneyo kunye nobude bokusetyenziswa kwezihluzo, akulunganga ukumisela umgangatho wezihluzi.Umgangatho wesixhobo kufuneka uqwalaselwe kuqala kule miba ilandelayo:

1. Umgangatho wephepha lokucoca

Iphepha lokucoca elisemgangathweni kunye nephepha lokucoca elikumgangatho ophantsi ziyafana ukusuka phezulu.Kuphela ngokuhlolwa phantsi kwezixhobo zokuhlola zefektri yobungcali, kunokubakho umahluko ocacileyo.Umgangatho wephepha lokucoca unxulumene nokusebenza kakuhle kwesihluzo.Kukho ukungcola okuninzi, i-iron kunye nothuli kwinkqubo, kunye nephepha lokucoca lokucoca ukungcola, isinyithi kunye nothuli.

2. Ukusebenza kakuhle kokucoca kwesihluzo

Ikakhulu igqitywe ngumgangatho wephepha lokucoca elisetyenziswe kwisihluzo.Ukuphumelela kokucoca kwesihluzi kungaphezulu kwe-96% ukuba ithathwe njengemveliso efanelekileyo.Ngexesha elifanayo nakwindawo enye, ukusetyenziswa kwezihlungi ezivela kubakhiqizi abahlukeneyo kuyahluka.Umahluko ocacileyo xa i-injini iqalwa, ngexesha lenkqubo yokuqhuba, imvakalelo yomqhubi we-injini kunye nenqanaba lomsi we-exhaust gas yemoto yahluke kakhulu xa injini ilungiswa kwaye iindawo zigugile.

3. Iphepha lokucoca kunye ne-end cap bonding material

Ngephepha lokucoca elisemgangathweni, kukwakho nokuncamatheliswa komgangatho olungileyo.Ukuba ukhetho alufanelekanga, iphepha lokucoca kwisihluzi aliyi kuqiniswa ngokuqinileyo kwi-caps ephezulu kunye nesezantsi.Xa ioli idibene ngexesha lokusetyenziswa, kulula ukuwa kwaye ayinakho ukunamathela.Ibangela isekethi emfutshane kwaye ayikwazi ukuhluza.

4. Isiqinisekiso senkqubo yemveliso.

Ukusuka kumphezulu, iphepha lokucoca kunye nephepha lokucoca alikwazi ukunamathela kunye.Ukuhanjiswa kufuneka kubonwe ekukhanyeni.Ukuba akukho kuhanjiswa kokukhanya phantsi kokukhanya, ukunamathela kwephepha lokucoca kuya kuchaphazela ukuhamba kwefayile yonke, ubomi bufutshane, kubangele amandla anganeleyo, ngokomzimba, kwaye kunzima ukususa uthuli ngexesha lokucoca.Isihluzi esilungileyo asinamatheli phakathi kwamaphepha okucoca, sinokuhanjiswa kokukhanya okuqinileyo, sifanelekile kumgangatho wamva nje we-injini, sinobomi obude benkonzo, kwaye kulula ukusicoca.

5. Inkqubo yokucoca

Ukukhetha izinto ezikumgangatho ophezulu ukuvelisa izihluzi, inkqubo yokuvelisa inkxaso yokuqinisekisa umgangatho weemveliso.Maninzi amakhonkco emveliso yesihluzo.Indlela yokuqinisekisa ukuba ifayile yokucoca inokukhusela kwaye ihlambulule ngexesha lokusetyenziswa, kwaye inokuqinisekisa ukuhamba kunye nokuqinisekisa ukusebenza okuqhelekileyo kwe-injini, idinga isiqinisekiso senkqubo yekhonkco nganye yenkqubo yokuvelisa.

Qhagamshelana nathi

_副本1.jpg)