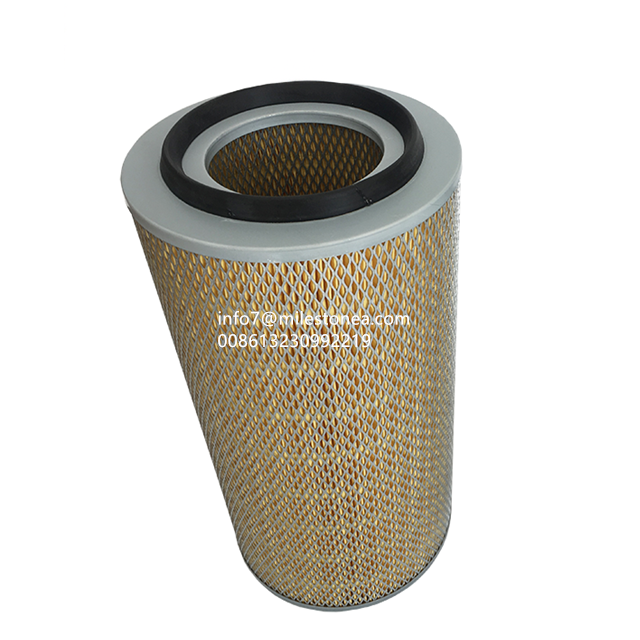

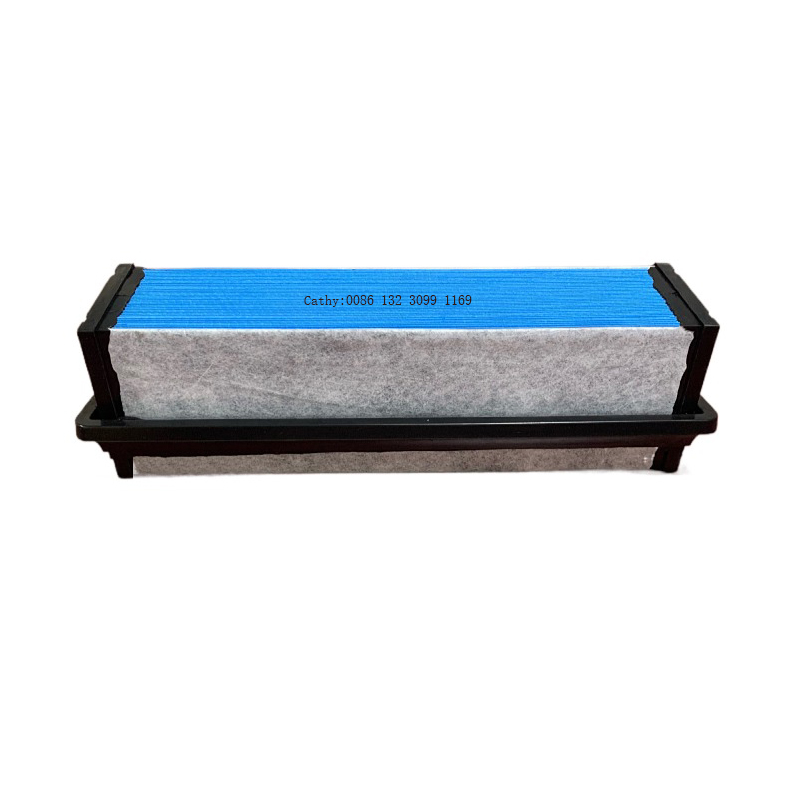

I-injini yelori yokucoca umoya ikhatriji P785589

Ikhatriji ye-Injini yokucoca umoyaP785589

Susa iinkcukacha

Isicelo:Isistim yeHydraulic Filter

Umsebenzi:Ukususa ubumdaka

Uhlobo:Hlunga

Ulwakhiwo:Ikhatriji

Isimo:Entsha

Indawo yokubonisa:Akukho

Ukuhlolwa kwevidiyo okuphumayo:Kunikiwe

INgxelo yoVavanyo loomatshini: Inikezelwe

Uhlobo lweNtengiso: iMveliso eNtsha yowama-2020

Iwaranti yamacandelo angundoqo: Unyaka o-1

Iwaranti: 1 Unyaka

Indawo yeMvelaphi:CN;HEB

Imizi-mveliso eSebenzayo:Ulwakhiwo lweeVenkile zeMathiriyeli

Imizi-mveliso eSebenzayo:Iplanti yokuVelisa

Imizi-mveliso eSebenzayo:Iivenkile zokulungisa oomatshini

Imizi-mveliso eSebenzayo:Imisebenzi yokwakha

Imizi-mveliso eSebenzayo:Amandla kunye neMigodi

Imizi-mveliso eSebenzayo:Iivenkile zokutya & neziselo

Imizi-mveliso eSebenzayo:INkampani yeNtengiso

Imizi-mveliso eSebenzayo:Isixhobo sokuHlunga seShishini

Ubunzima (KG):2

Amacandelo anguNdoqo:isihluzi

Ucalucalulo lokucoca okulungileyo nokubi

Zonke izihluzi zezokukhusela iinxalenye ze-injini, zicocekile, zandise ubomi benkonzo ye-injini, ukusuka kumphezulu wezihluzo ezahlukeneyo kunye nobude bexesha lokucoca lusetyenziswayo, akulunganga ukugweba ukuba isihluzo silungile okanye sibi, kwaye icebo lokwenyani ligwetyiwe.Enoba umgangatho ulungile okanye umbi, kufuneka kuqala siqwalasele ezi nkalo zilandelayo:

1. Umgangatho wephepha lokucoca

Iphepha lokucoca elinomgangatho olungileyo kunye nephepha lokucoca elinomgangatho ophantsi liyafana kumphezulu.Kuphela ngokuhlolwa phantsi kwezixhobo zokuhlola zefektri yobungcali, kunokubakho umahluko ocacileyo.Umgangatho wephepha lokucoca unxulumene nokusebenza kakuhle kwesihluzo.Kukho ukungcola okuninzi, intsimbi, nothuli kwinkqubo.Izihluzo zephepha ezikumgangatho ophantsi wokucoca ukungcola okuncinci, intsimbi, kunye nothuli, olungenakukhusela i-injini, kunye neendawo ezinxulumene ne-injini kulula ukunxiba.

2. Ukusebenza kakuhle kokucoca kwesihluzo

Ikakhulu igqitywe ngumgangatho wephepha lokucoca elisetyenziswe kwisihluzo.Ukusebenza kakuhle kokucoca kwesihluzi kungaphezulu kwe-96% ukuba ithathwe njengemveliso efanelekileyo.Ngexesha lokuqalisa kunye nokuqhuba i-injini, imvakalelo yomqhubi we-injini kunye nenqanaba lomsi we-exhaust gas yesithuthi yahluke kakhulu ekugugile kunye nokukrazula kwamalungu e-injini ngexesha lokulungiswa.

3. Izinto ezincamathelayo kwiphepha lokucoca kunye ne-end cap

Ngephepha elilungileyo lokucoca, kufuneka kubekho ukuncamatheliswa komgangatho olungileyo.Ukuba ukhetho alufanelekanga, iphepha lokucoca kwisihluzi aliyi kuqiniswa ngokuqinileyo kwi-caps ephezulu kunye nesezantsi.Ngethuba lokusetyenziswa, ioli iya kuwela ngokulula kwaye ingabikho, okubangela isiphaluka esifutshane, akukho siphumo sokucoca.

4. Isiqinisekiso senkqubo yemveliso

Ukusuka kumphezulu, iphepha lokucoca alikwazi ukunyathela kwiphepha lokucoca, kwaye ukuhanjiswa kokukhanya kufuneka kubonwe phantsi kokukhanya.Ukuba akukho ukuhanjiswa kokukhanya phantsi kokukhanya, ukunamathela phakathi kwamaphepha okucoca kuya kuchaphazela ukuhamba kwekhekhe lokucoca umoya, kwaye ubude bobomi buya kuba bufutshane, kubangele amandla anganeleyo kunye nobuthathaka, kwaye kunzima ukususa uthuli ngexesha. inkqubo yokucoca.Isihluzi somoya esilungileyo asinamatheli phakathi kwamaphepha okucoca, sinokuhanjiswa kokukhanya okuqinileyo, sifanelekile kwimigangatho yokungenisa umoya we-injini, sinobomi obude benkonzo, kwaye kulula ukusicoca.

5. Inkqubo yokucoca umoya

Ukukhetha izinto ezikumgangatho ophezulu ukuvelisa izihluzi, inkqubo yokuvelisa inkxaso yokuqinisekisa umgangatho weemveliso.Maninzi amakhonkco emveliso yesihluzo.Indlela yokuqinisekisa ukuba isihluzo sinokukhusela kwaye sihlambulule ngexesha lokusetyenziswa, kunye nokuqinisekisa ukuhamba kunye nokuqinisekisa ukusebenza okuqhelekileyo kwe-injini, kufuna isiqinisekiso senkqubo yekhonkco nganye yenkqubo yokuvelisa.